Discover Prefabricated Holiday Cottages by Thermoteq Prefab Houses Ltd

7 Good Reasons to Choose Thermoteq’s Exceptional Prefabricated Holiday Cottages in Kenya

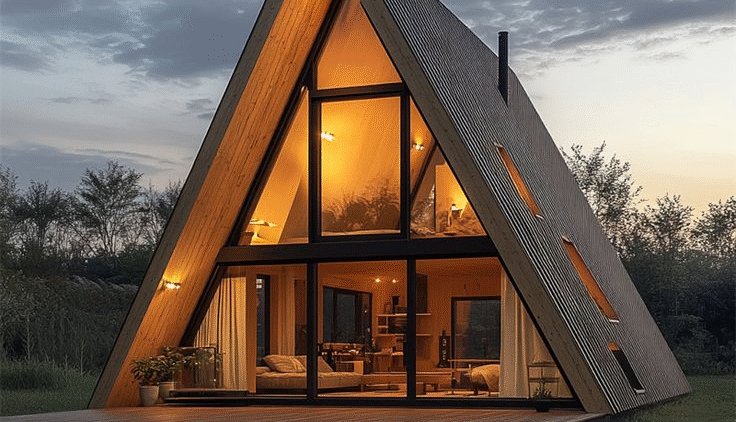

A frame cottage

In today’s fast-moving world, more people are looking for affordable, eco-friendly, and quick-to-build holiday homes. Whether it’s for a personal escape, vacation rental income, or tourism investment, prefabricated holiday cottages are becoming the top choice. Prefabricated construction makes owning a modern holiday home easier than ever. Leading this innovation is Thermoteq Prefab Houses Ltd, Kenya’s top prefab housing expert.

What Are Prefabricated Holiday Cottages?

Prefabricated (or prefab) cottages are built off-site in a factory, then delivered and assembled at the final location. This process shortens construction time and improves quality control. Unlike traditional methods that can take months, prefab homes can be move-in ready in just weeks.

Thermoteq Prefab Houses Ltd uses cutting-edge technology and environmentally friendly materials. The result? Stylish, strong, and energy-efficient cottages for modern living.

Why Choose Thermoteq Prefab Houses Ltd?

We are a trusted name in modular holiday home construction. Here are 7 powerful reasons why you should work with us:

1. Fast and Reliable Construction

Building in a controlled factory environment reduces delays. Once construction is complete, we transport and install your cottage quickly. Weather interruptions don’t slow the process.

2. Affordable Without Compromising Style

With efficient design and material use, Thermoteq keeps costs low. You get an affordable holiday cottage that still looks beautiful and modern.

3. Sustainable and Eco-Friendly

We care about sustainability. Our prefab cottages use insulated wall panels, energy-saving materials, and solar-ready roofing. Construction waste is minimized, which helps the planet.

4. Personalized Design Options

Choose from a variety of layouts, finishes, and styles. Whether you want a rustic getaway or a sleek modern design, our company builds according to your vision.

5. Perfect for Vacation Rentals & Tourism Investment

Many people are entering the vacation rental market through platforms like Airbnb. Prefab homes offer a fast way to start earning rental income. They’re also perfect for eco-lodges, resorts, and family getaways.

As demand for affordable and green tourism grows, prefabricated holiday cottages are becoming more popular. Thermoteq helps clients create homes that meet both personal and business needs.

6. Strong, Durable, and Built to Last

Our design homes meet high-quality standards. Their skilled team includes engineers and designers who ensure every unit is tested and built to last. These cottages withstand Kenya’s coastal winds, mountain chill, and inland heat.

Top-grade materials are used from the base to the rooftop. You get a home that performs well and requires little maintenance.

7. Legal and Compliance Support

Building permits and codes can slow a project. Thermoteq helps clients handle all legal documents and approvals. This ensures your project moves smoothly and meets Kenyan construction standards.

Where Can You Install a Prefab Cottage?

Prefabricated holiday cottages can be placed in many settings:

-

By the lake or river

-

In the mountain landscapes

-

Along the coast

-

On farmland

-

At safari lodges or remote retreats

All you need is basic road access and utilities. These cottages are also portable, so you can relocate them if needed.

A Modern Way to Build

Prefab construction is the future. It’s faster, cleaner, and more affordable than traditional building. Thermoteq gives you more than just a home—they deliver a complete, stress-free experience.

From design to delivery, every step is covered. Your dream cottage becomes a reality in just a few weeks.

Ready to Build Your Getaway?

Thermoteq Prefab Houses Ltd is ready to bring your dream to life. With flexible designs, expert builders, and fast turnaround, your perfect holiday home is closer than you think. Hey, remember you can as well come with your custom design and actualize it with us.

Contact Thermoteq Prefab Houses Ltd today and start building your prefabricated holiday cottage in Kenya.